Celebrating Ahlstrom's New Product Development Space

Key Takeaways

- Ahlstrom Manufacturing produces world class paper filtration products

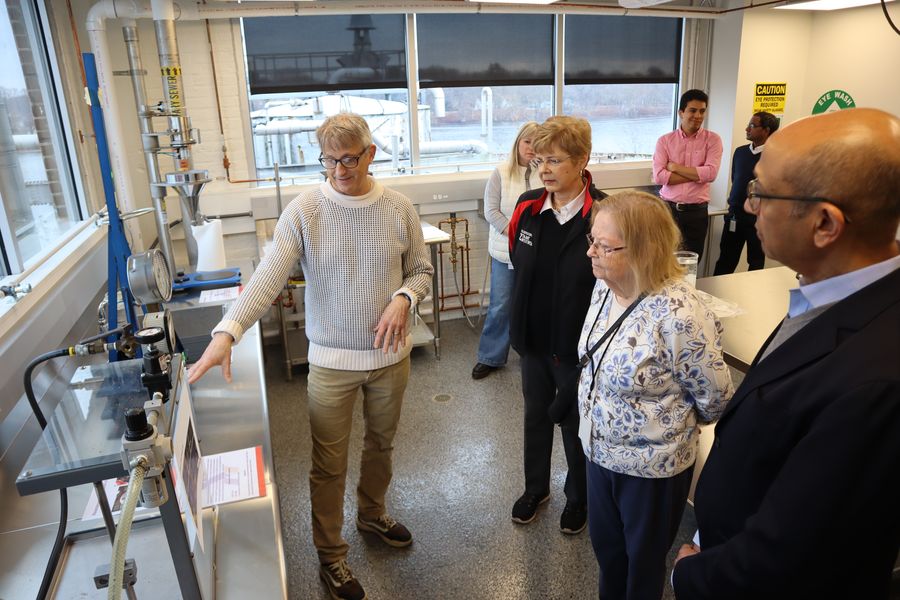

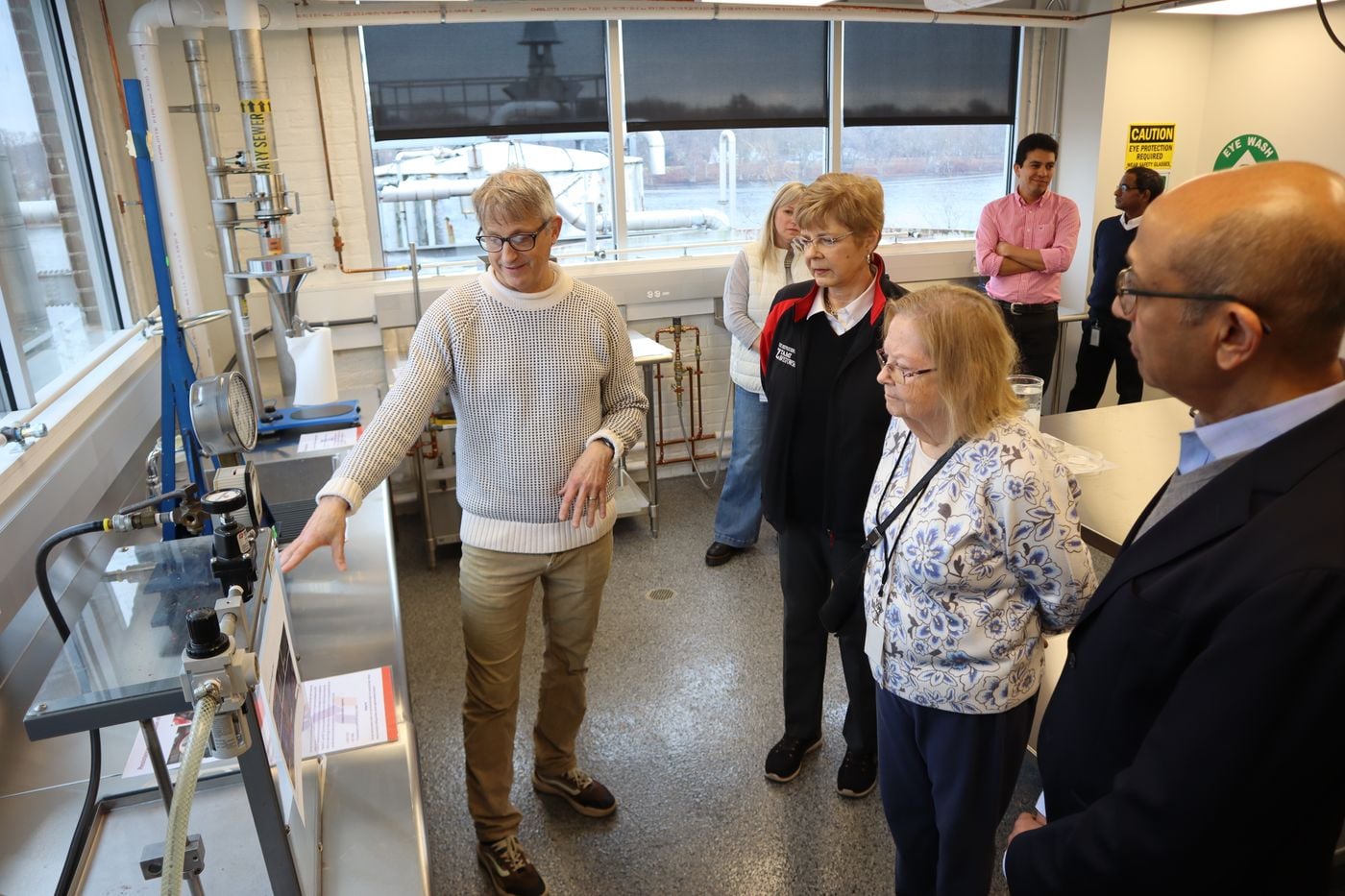

It was a pleasure to celebrate the Grand Opening of Ahlstrom’s Windsor Locks Product Development space today, along with CT Chief Manufacturing Officer Kirti Patel, Rep. Jane Garibay and others. This newly renovated area will provide a dedicated space for product testing and development.

As a pillar of the Windsor Locks manufacturing community, Ahlstrom has been in business for more than 250 years – it began as the Dexter Company in 1767 - and produces world-leading fiber-based products that are used to protect and purify businesses, hospitals, construction sites, and more. In fact, market-leading surgical gown fabrics are made right here in Windsor Locks!

The Windsor Locks facility is Ahlstrom’s second largest global site, employs 300+ people and operates around the clock year-round.

The company portfolio is vast and includes applications and products across myriad industries for the automotive and transportation, healthcare, food and beverage, industrial goods, e-commerce and retail industries. Products made in Windsor Locks include medical grade materials such as level 4 surgical gowns and drapes which comprise about 70% of this facility’s output, the fiber paper used for Keurig K-Cups and tea bags (the tea bag was invented right here in this facility!), and other products such as wall coverings.

The company is fully invested in sustainability and requires a significant amount of water in its production and diverts and returns 6 million gallons of water from the Connecticut River daily. The water is cleaned on its way into the facility and is returned to the river much cleaner than when it was brought in. The plant also has also made major investments in gas turbine technology to cover its own electricity needs and feeds excess power production into the grid.

For more information: https://www.ahlstrom.com/